How Kaltra Innovates with Microchannel Technology

Microchannel technology is rapidly transforming the landscape of heat exchangers and cooling systems. Kaltra, a leader in this sector, has been at the forefront of these advancements, pushing the boundaries of thermal efficiency and energy savings.

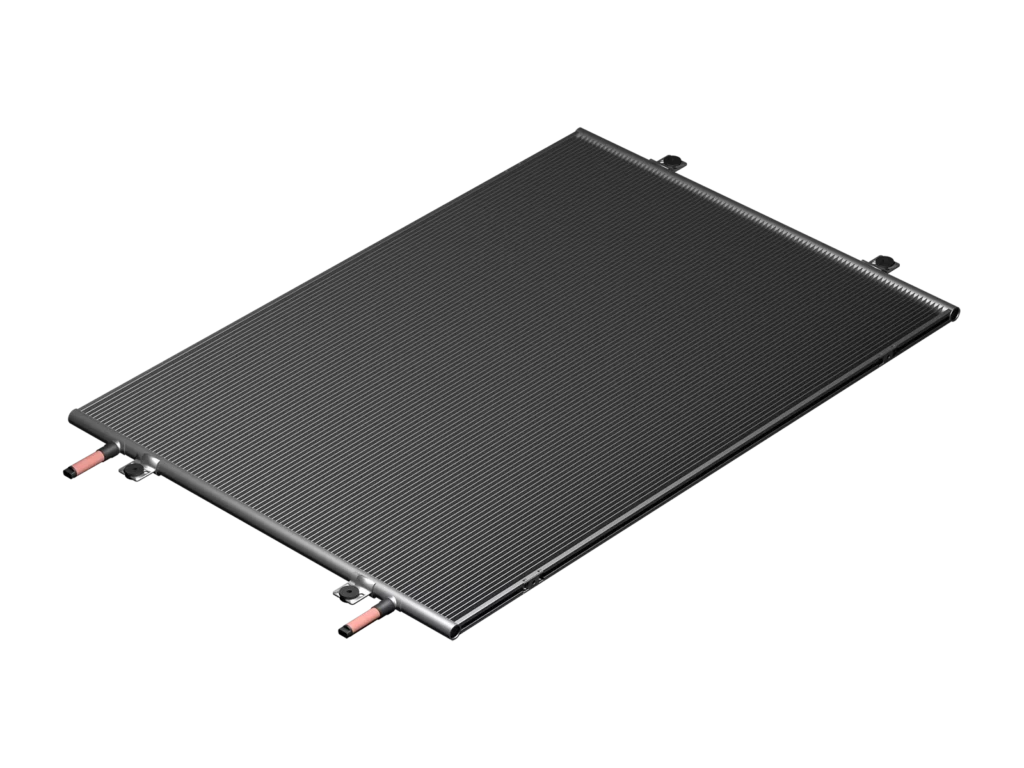

Understanding Microchannel Technology

Microchannel heat exchangers consist of numerous small channels that facilitate heat transfer between two fluids. This design significantly increases the surface area available for heat exchange while minimizing the amount of refrigerant needed. The result is a more compact and efficient system compared to traditional heat exchangers.

Advantages of Microchannel Designs

- Enhanced Efficiency: The higher surface area-to-volume ratio leads to improved thermal performance.

- Reduced Weight: Microchannel heat exchangers are typically lighter, allowing for easier installation and lower structural support requirements.

- Lower Refrigerant Charge: With a reduced volume of refrigerant, these systems are not only more cost-effective but also environmentally friendly.

Kaltra has been instrumental in maximizing these advantages through its innovative designs and manufacturing processes. Their focus on microchannel technology ensures that the products they deliver are among the most efficient on the market.

Applications and Case Studies

Kaltra’s microchannel technology has found applications across various industries, from HVAC to industrial cooling systems. For instance, their systems are widely used in commercial air conditioning units, where space and energy efficiency are paramount.

Case Study: High-Performance Cooling for Data Centers

Data centers require robust cooling solutions to maintain optimal operating temperatures. One of Kaltra’s recent deployments involved integrating their microchannel heat exchangers into a major data center’s cooling system. The result was a 30% reduction in energy consumption compared to previous setups, highlighting the effectiveness of this technology in high-demand environments.

Future Trends in Microchannel Technology

The future of microchannel technology looks promising, with ongoing research and development aimed at further enhancing its capabilities. Innovations in materials and manufacturing techniques will likely lead to even more efficient designs, enabling applications in areas such as renewable energy systems and electric vehicles.

Kaltra remains at the forefront of these developments, continuously exploring how to push the limits of microchannel technology. Their commitment to innovation is evident in their extensive portfolio and focus on providing tailored solutions that meet the unique needs of their clients.

Summary of Innovations

- Integration of advanced materials to enhance durability and performance.

- Smart technologies that allow for real-time monitoring and optimization of system performance.

- A focus on sustainability through reduced environmental impact and energy consumption.

A Result

Kaltra’s dedication to microchannel technology is not just about efficiency; it’s about transforming industries. By harnessing the potential of this innovative approach, Kaltra is setting new standards for performance and sustainability. Their ongoing efforts to refine and expand the capabilities of microchannel heat exchangers will undoubtedly lead to exciting developments in the years to come. For more information on their offerings, visit Kaltra.